Firewood processor : XYLOG 800

Wood processor for the industrial production of firewood. Wood diameter up to 800 mm.

Designed to adapt to your production type, this firewood processing machine features a 4-meter V-shaped feeding conveyor to easily handle logs of any length. Three independent clamps conform to the log's shape to hold it in place during sawing.

Similar to its counterparts, the cutting length of the XYLOG 800 is adjustable from 250 to 500 mm to meet various demands. Depending on the chosen model, the cutting can be done by guide bar or circular saw blade.

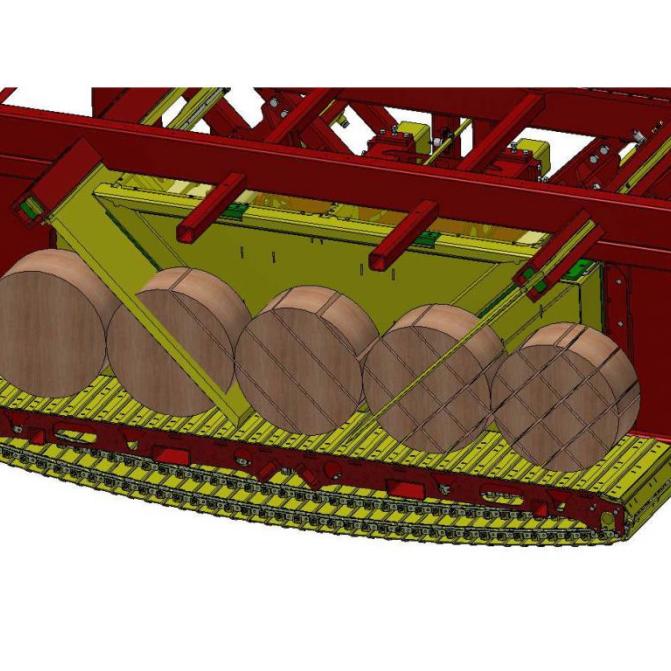

For even greater efficiency, the cut logs are directed to a buffer zone and then into the splitting channel. This channel, consisting of a step-by-step adjustable metal conveyor, ensures a regular and controlled feed of logs to the splitting mechanism, which is composed of two independent blades.

Versatile, this firewood processor has an air-conditioned cabin with WIFI connectivity to provide comfort to firewood professionals.

A log cleaner XYLOCRIBLE and a palletizer XYLOPACK can be added at the exit of the evacuation conveyor for a complete installation.

- Do you want to know the availability of the product ?

- Would you like to request information or advice on this product ?

- Would you like to discover the machine near you, at a trade fair or at a reseller ?

On video : Firewood processor : XYLOG 800

Main Features

- Maximum cutting diameter 800 mm.

- Cutting system with chain guide or circular saw blade.

- Cutting length adjustable from 250 to 500 mm. Length of cut managed by a hydraulically adjustable stop, with a backward movement of the stop at the time of cutting to avoid constraining the sawing.

- Combination feeder with 3- or 4-chain deck: up to 8 m of useful chain (for fixed station machine). Ideal for logs 4 to 8 m long.

- Timber fed by chain conveyor then V-shaped channel, min. length 4 m. For good feeding of timber to the cutting area, even short lengths.

- 3 independent wood holding clamps for cutting. Whatever the shape of the wood, the clamps are in contact with it.

- Possibility to evacuate directly the pieces that are not to be split without passing through the splitting cross (Ø 200 mm max). The wood scraps can also be evacuated to the rear thanks to the pallet.

- Buffer zone with a 3-metre long belt for continuous feeding of logs to the splitter.

- Splitting system with two independent blades, with 3 independent pressers for a good hold of the wood.

- ISO POWER system on the blades, to manage the speed of the blades according to the power required.

- XYLOMETER® : Automated system for measuring the volume of wood produced.

- On the splitting area, a metal conveyor with an adjustable pace feed from 40 to 300 mm for the size of the logs.

- Design according to your requirements for stationary machines.

Technical characteristics

| Model |

| Splitting power |

| Cutting Ø |

| Length of cut |

| Cutting system |

| Chain |

| Splitting system |

| Loading conveyor |

| Infeed deck |

| Discharge conveyor |

| Drive |

| XYLOG 800 |

| 16 Tons with automatic speed with continuous varation ISO POWER |

| Max. 800 mm |

| Adjustable from 250 to 500 mm |

| SUPERCUT with harvesting head type guide bar - Length 1130 mm - type 0,404 OR Circular saw blade Ø 1830 mm - Thickness 7 mm - 80 carbide teeth |

| Automatic tensioning and self-lubrication |

| 2 independent blades with 3 pressers for good wood retention |

| Usable length 8 m with 3 or 4 chains |

| A chain then V channel |

| Length 8 m and width 700 mm with independent strips and metal bars Height adjustable from 1,30 to 5 m Adjustable over 6 m |

| 37 kW three-phase electric motor for chain saw unitor 55 kW for the blade sawing unit + 1 x 37 kW three-phase electric motor for the splitting unit |